Contact Us

We received your contact information and a representative will connect with you soon.

Thank you.

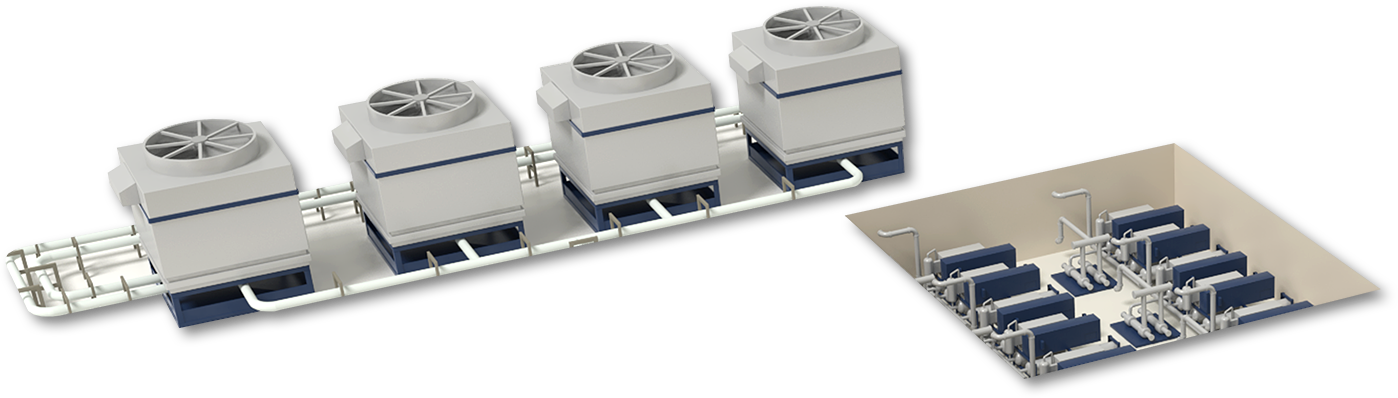

Cooling Water Systems

Nalco Water's 3D TRASARTM Cooling Water Technology can detect system variability, determine the correct response, and deliver efficiencies of operation and cost. This has enabled fabs to use reclaimed process rinse waters as cooling tower make-up and, in certain cases, eliminate the use of fresh water for cooling towers – all with assured asset preservation.

More 3D TRASAR Cooling Water Program benefits:

- Scale and fouling prevention results in lower energy consumption

- Reduced water with increased cycles of concentration

- Real-time system data via performance dashboards

- Assurance that system experts are watching your system 24/7

- In one case, 1.2 billion gal/water were saved in five years with no loss of chiller performance in 17 years

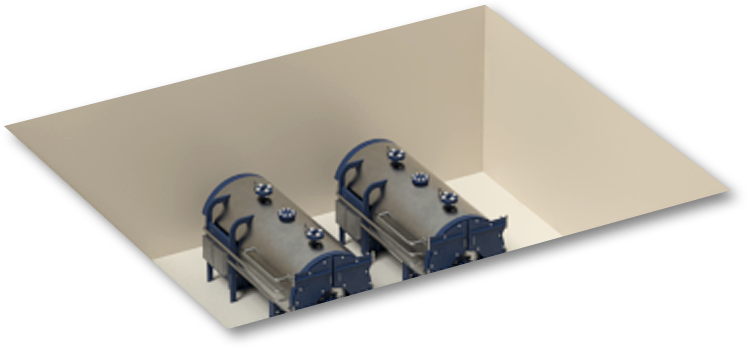

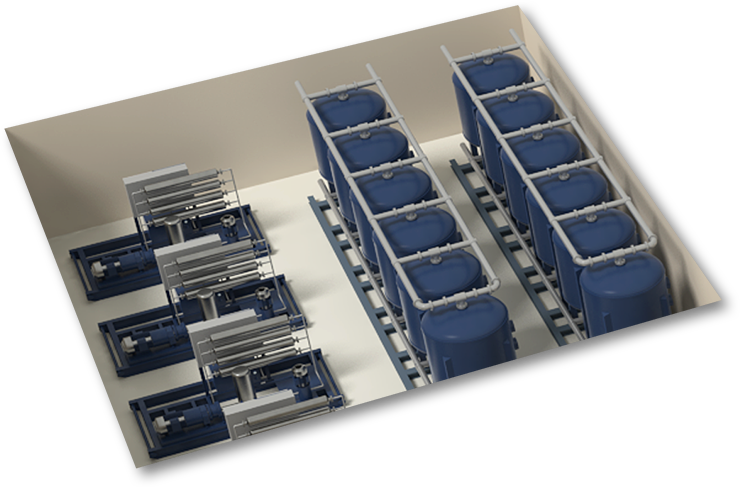

Boiler Systems

Nalco Water's 3D TRASARTM Boiler Technology improves competitive advantage and decreases total operating costs. We help you produce reliable, safe, and cost-effective steam using a total system approach.

More reasons to partner with Nalco Water:

- Oxygen scavengers, internal treatment, and condensate corrosion inhibitors

- Technology that monitors and controls real-time internal treatment and pre-boiler system corrosion

- Steam system protection with programs tailored for your needs

- Water and energy savings delivered through optimized programs

- Savings in fuel, water and extended asset life can exceed hundreds of thousands of dollars

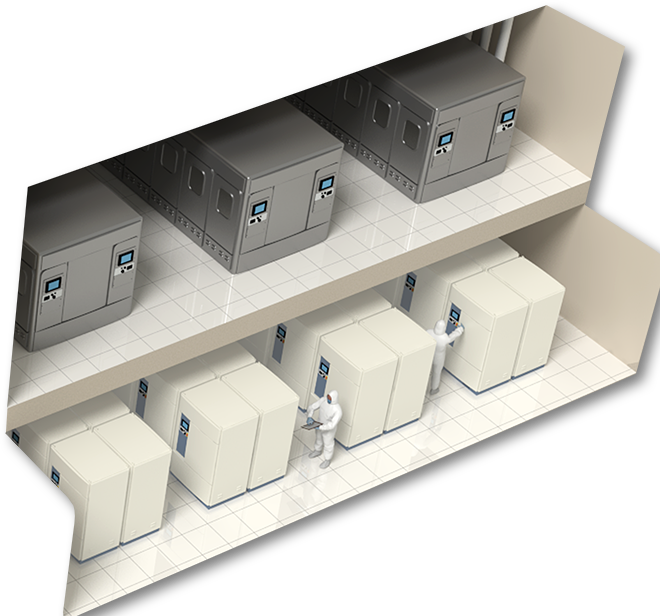

Fab and Sub Fab

Nalco Water's work on PCCL (Process Critical Closed Loops) enables semiconductor tool manufacturers to ensure higher uptime levels, and avoid problems within tools' cooling water circuits. Additionally, ongoing work on process metrologies creates opportunities for chip producers to improve process visibility and reduce inefficiencies and scrap.

More reasons to partner with Nalco Water:

- Tool-specific water treatment solutions

- Global deployment capabilities

- Analytical support

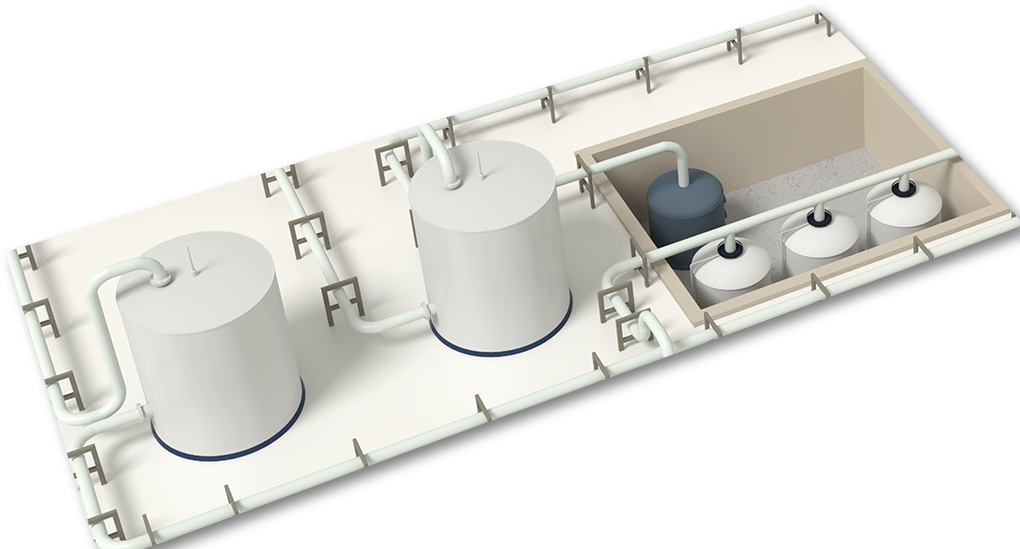

Waste Water

Nalco Water's capabilities to help control heavy metals and fluoride in fab wastewater and ensure regulatory compliance and reduce total cost of operation.

More reasons to partner with Nalco Water:

- DBOOM capabilities (Design, Build, Own, Operate and Maintain) for specific wastewater challenges

- NalmetTM heavy metal removal programs for better treatment of chelated metal streams with improved aquatic toxicity levels

- Reduced hazardous sludge generation and lower disposal costs

- Examples of savings have exceeded $5 million

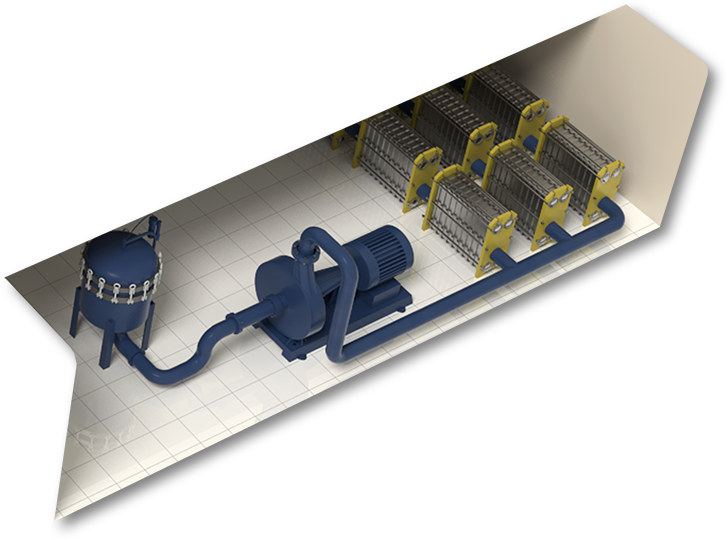

Process Cooling Water (PCW)

Nalco Water's emphasis on controlling scale, corrosion, and microbio in cooling water helps protect the water that ensures a reliable manufacturing environment in the fab.

More reasons to partner with Nalco Water:

- 3D TRASARTM Cooling Water Technology gives real-time process visibility to critical water parameters including conductivity, corrosion rates, hydraulic losses and pH

- TRAC cooling water programs ensure excellent corrosion control for a wide range of metallurgies across a broad range of conductivity requirements

- Nalco Water filtration systems help to minimize system deposits in small tolerance cooling water systems to ensure cooling water supply

Ultra Pure Water

Nalco Water's PermaCareTM product line and control technologies help prevent RO problems and ensure high quality permeate.

More reasons to partner with Nalco Water:

- Highly effective antiscalants to prevent mineral deposits from membrane build-up, causing fouling and downtime

- 3D TRASARTM Membrane Technology for:

- Precise antiscalant dosing

- Protection of membranes from oxidant spikes

- Optimization of recovery rates and cleaning schedules

- Cleaners specifically formulated to remove mineral scale, insoluble scale, organic fouling and microbial residues

- One multi-site customer experienced a 30% reduction in total operating cost

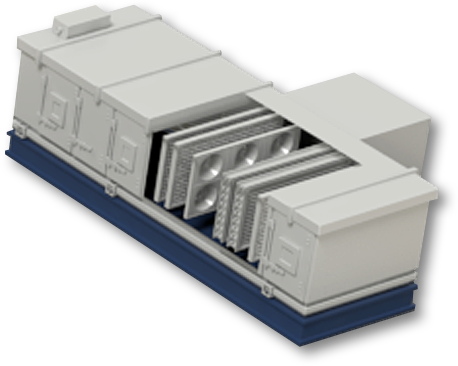

Air Handlers

Nalco Water's COIL-FLOTM coil cleaning and air filtration packages improve coil efficiency and air quality resulting in "more air, cooler air."

More reasons to partner with Nalco Water:

- Reduced air handler energy costs

- Lower filter expenditures

- Data-based documentation of energy savings

- Dedicated, trained cleaning staff

- COIL-FLO average payback is 10 months with examples of 11% reduction in electrical costs

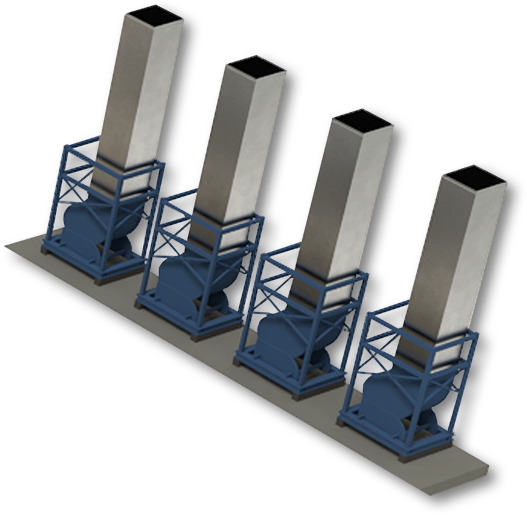

Scrubbers

Nalco Water's water treatment programs help ensure efficient scrubber performance and fab environmental compliance by controlling scale and microbial deposits.

More reasons to partner with Nalco Water:

- Increased air scrubber efficiency

- Controlled maintenance

- Prevention of scale and microbial deposits

- Hands-off chemical treatment programs