Contact Us

We received your contact information and a representative will connect with you soon.

Thank you.

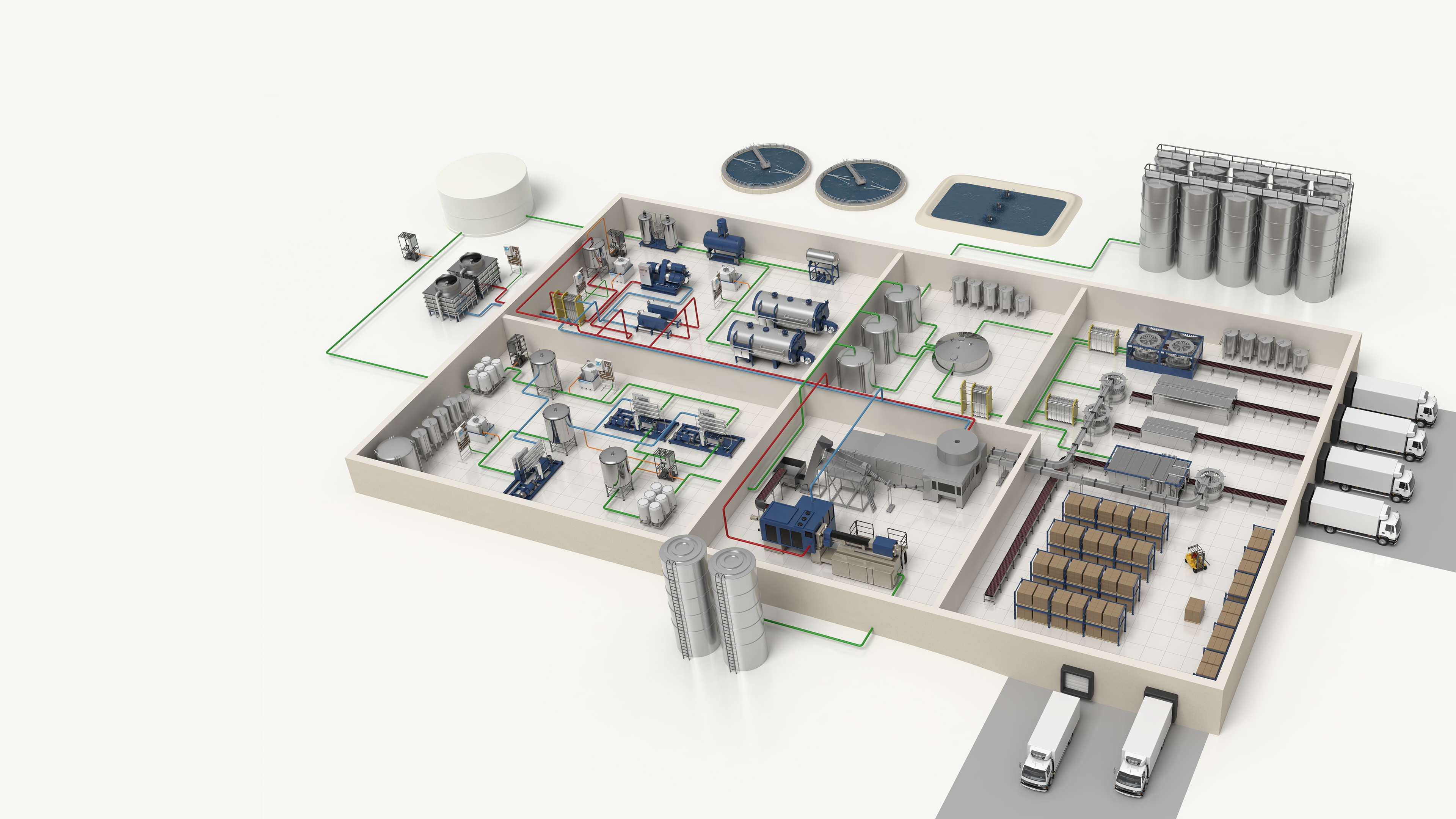

Source / Process Water Disinfection

AccuProTM, EnviroxTM, and NALDIOXTM on-site generation of Chlorine Dioxide offer these benefits to our beverage customers:

- Verification of Residual – Robust occident control that is dialed precisely into the residual required

- Effective Biocide at low concentrations; does not cause off-flavor in beverages

- Reliability – Monthly Preventative Maintenance (PM) assures plant that its system is running safely and smoothly

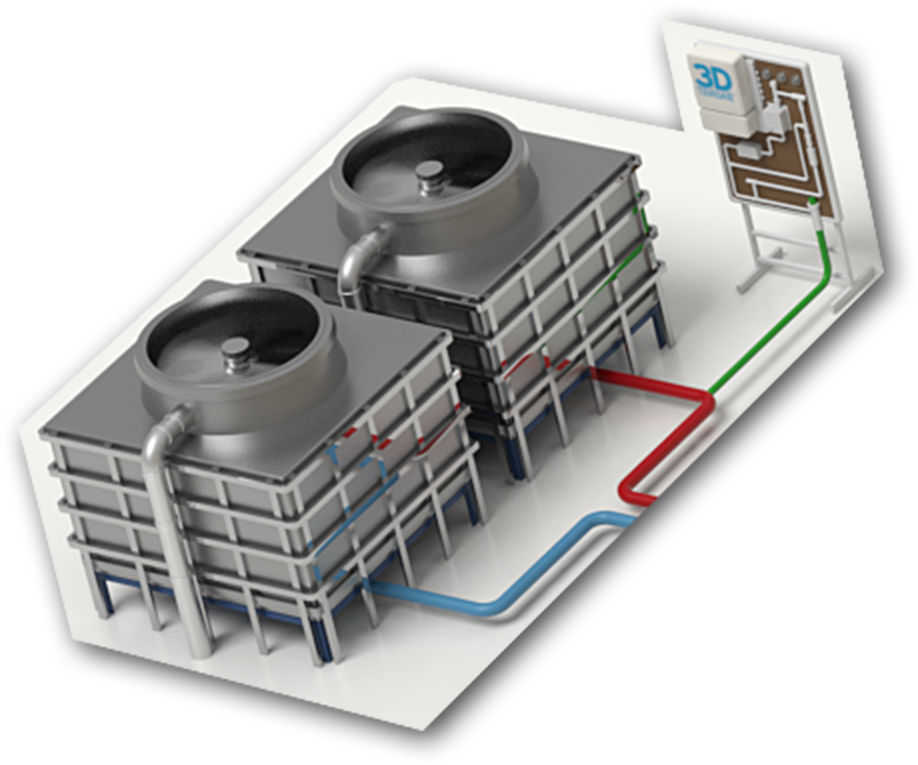

Cooling Water System

Nalco Water’s 3D TRASARTM Cooling Water Technology can detect system variability, determine the correct response, and deliver efficiencies of operation and cost. This has enabled beverage manufacturers to use reclaimed process rinse water as cooling tower make-up and, in certain cases, eliminate the use of fresh water for cooling towers – all with assured asset protection.

More 3D TRASAR Cooling Water Program benefits:

- Reduced energy with scale and fouling prevention

- Extended asset life through customized applications

- Water savings with increased cycles of concentration

- Access to real-time system data via performance dashboards

- Confidence that system experts are watching your system 24/7

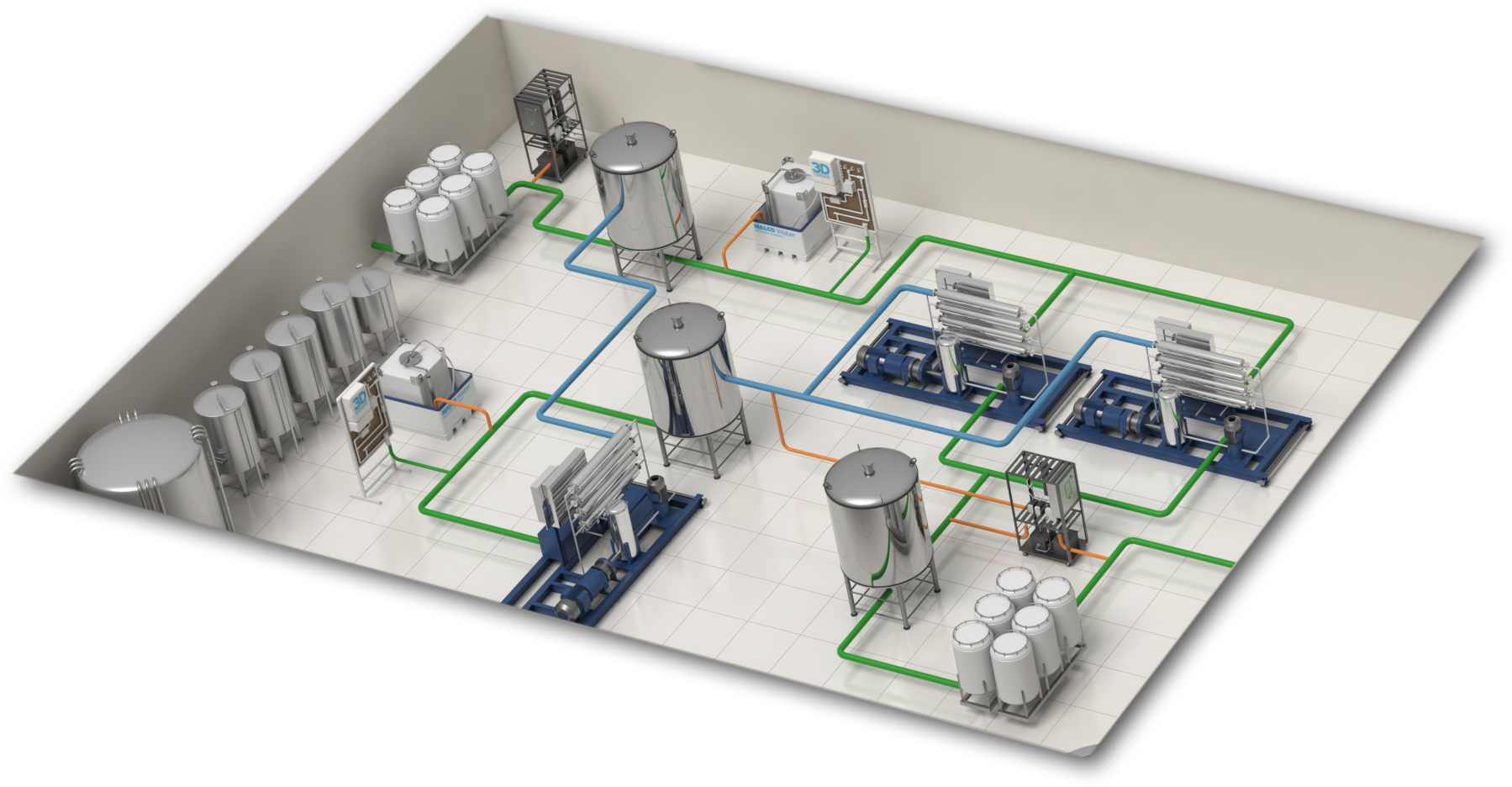

Water Room

Pretreatment Equipment and Services

From point-of-use water to polishing systems to temporary water, Nalco Water offers a complete line of services and equipment to meet the needs of a beverage operation.

Reverse Osmosis

RO Performance Services is a comprehensive program with 3D TRASARTM Membrane Technology, Automation, 24/7 Monitoring, PermaCareTM chemistry (NSF-60), CIP and expert services, to help ensure consistent quality & quantity globally.

3D TRASAR Technology for Membranes:

- Detects problems before they impact your operation

- Delivers powerful results including water and energy savings, prolonged membrane life and minimized downtime

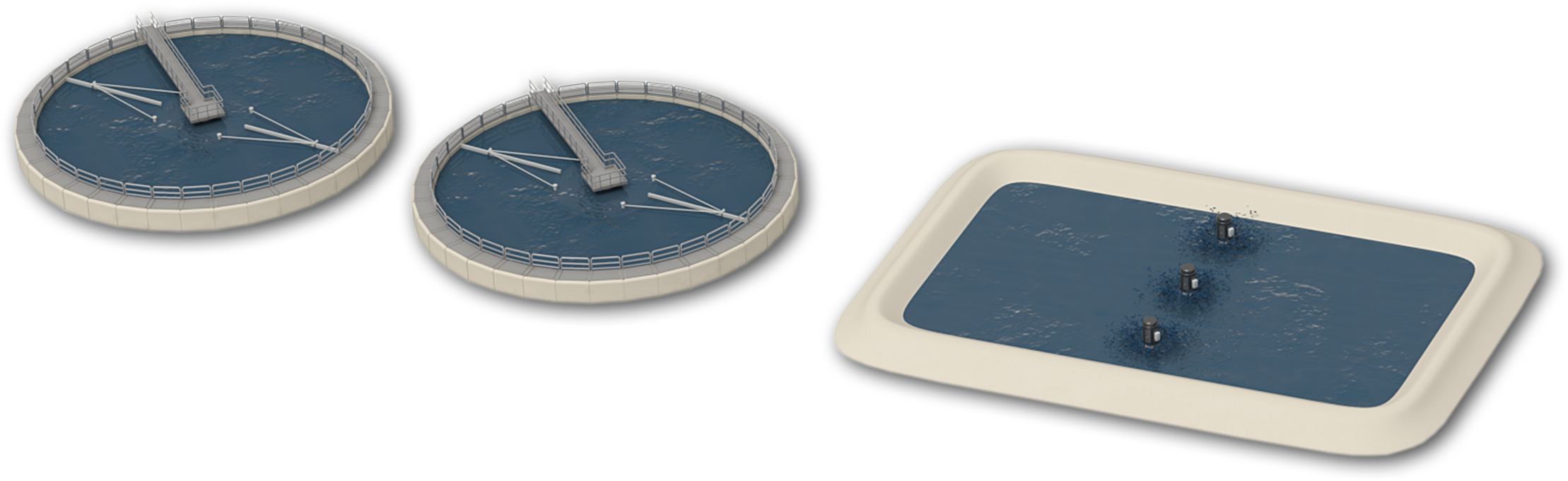

Waste Water System

As the leader in wastewater/raw water treatment, Nalco Water has the breadth of product line for all solid/liquid separation applications and supplemental offerings designed to help ensure regulatory compliance.

More reasons to partner with Nalco Water:

- Meet environmental discharge limits while reducing total cost of operation

- Optimize BOD/COD removal and TSS reduction with the possibility of reusing the effluent water within the beverage facility

- 3D TRASAR Technology for Waste Water/DAF optimizes chemical usage and treatment results

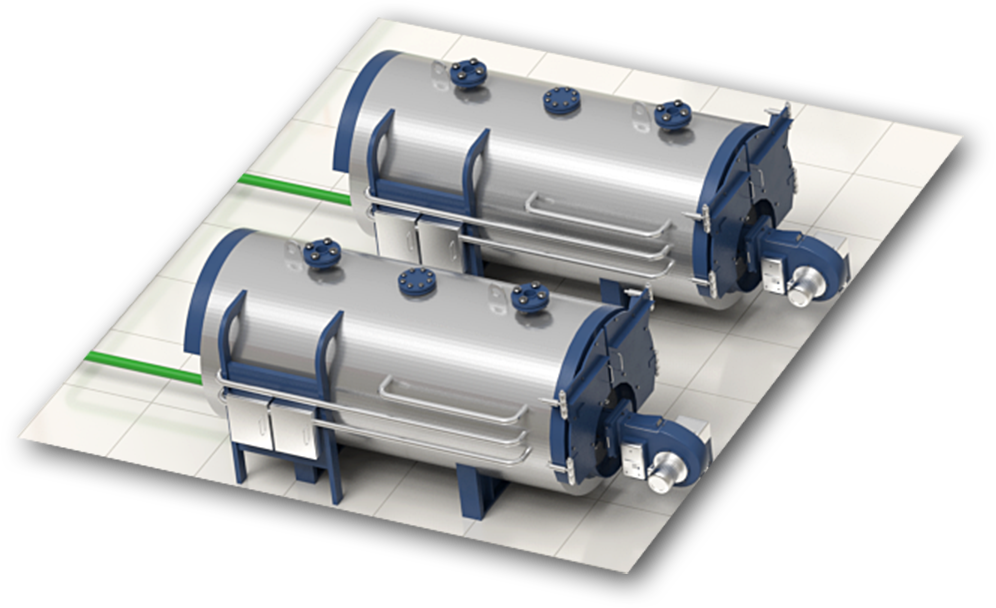

Boiler System

Nalco Water’s 3D TRASAR Boiler Technology helps you produce safe, reliable and cost-effective steam using a total systems approach.

More reasons to partner with Nalco Water:

- FDA-approved oxygen scavengers, internal treatment, and condensate corrosion inhibitors

- Technology that monitors and controls real-time internal treatment and pre-boiler system corrosion

- Fully automated hardness monitoring system that includes low level hardness measurement, upset detection, corrective action and communication of results

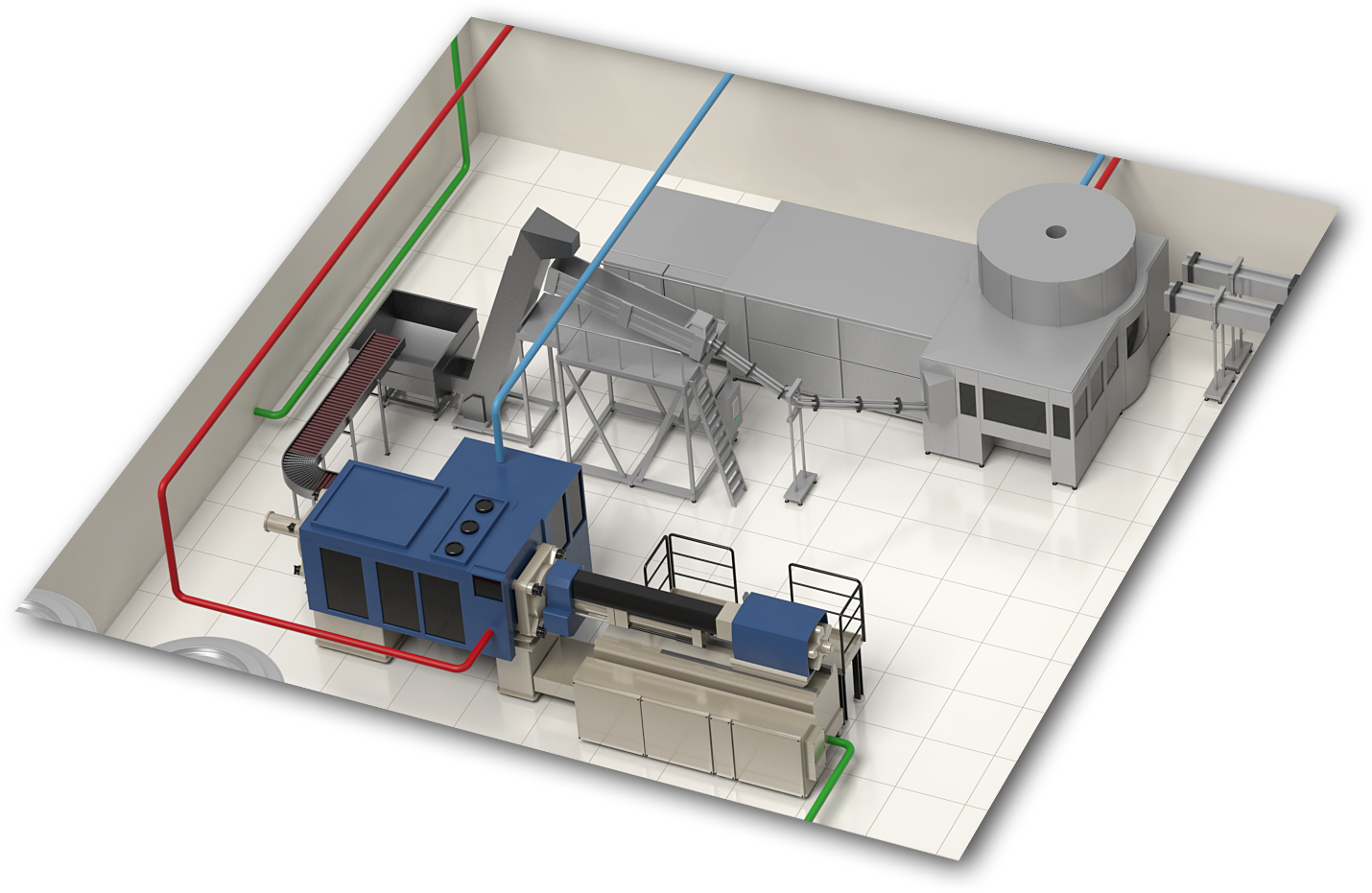

Injection / Blow Molding Systems

Nalco Water's comprehensive program for critical closed loops starts with an evaluation of the mechanical, operational, and chemical aspects of the chilled water cooling system. Cleaning and passivation of the closed cooling system, addition of corrosion inhibitor & biocide, side stream filtration and KPI monitoring results in significant improvement in cooling water quality and performance.

Benefits to your facility include:

- Extended blow molding machine asset life

- Reduced unplanned maintenance

- Optimum production volumes

- Lower total cost of operation

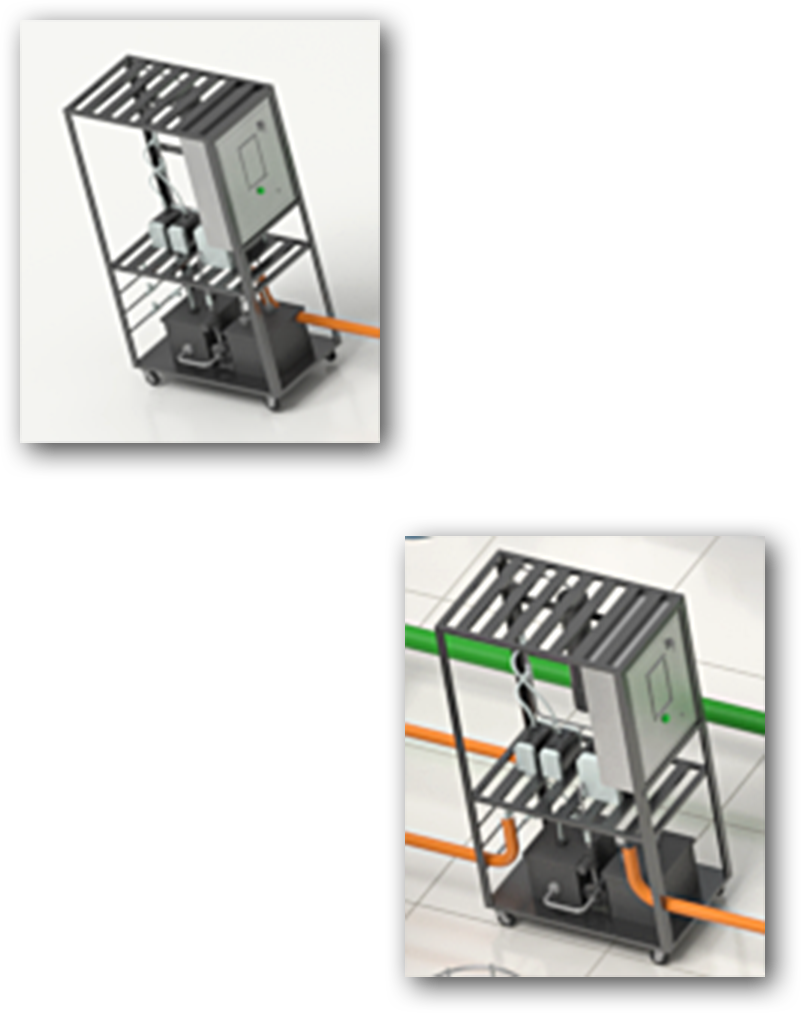

Clean–in–Place (CIP) Systems

Ecolab delivers optimal cleaning and sanitation results while helping assure food safety, quality and consistency across your beverage operations.

Our CIP Solutions include:

- Alkaline & Acid cleaners compatible with beverage equipment

- Peroxide addition for organic soil removal

- Microbial control without flavor carry over

3D TRASAR CIP Technology provides 24/7 visibility to all aspects of CIP wash operations including any deviations from cleaning SOPs. It verifies each CIP wash, telling customers if they are washing correctly and optimally each time. The insights and analysis provided enable greater confidence around food safety, enhanced product consistency and operational improvement opportunities.

More reasons to partner with Ecolab include:

- Improved product consistency

- Wash verification and record keeping

- Minimized downtime for cleaning

- Reduced water and energy consumption for cleaning

Fillers

Our Filler Hygiene Solutions enable beverage producers to keep dirt and micro activity to a minimum during production so that when lines are shut down to clean, cleaning time is cut in half.

Benefits for beverage facilities:

- Time and energy reduction

- Reduced equipment damage

- Reduced environmental recontamination

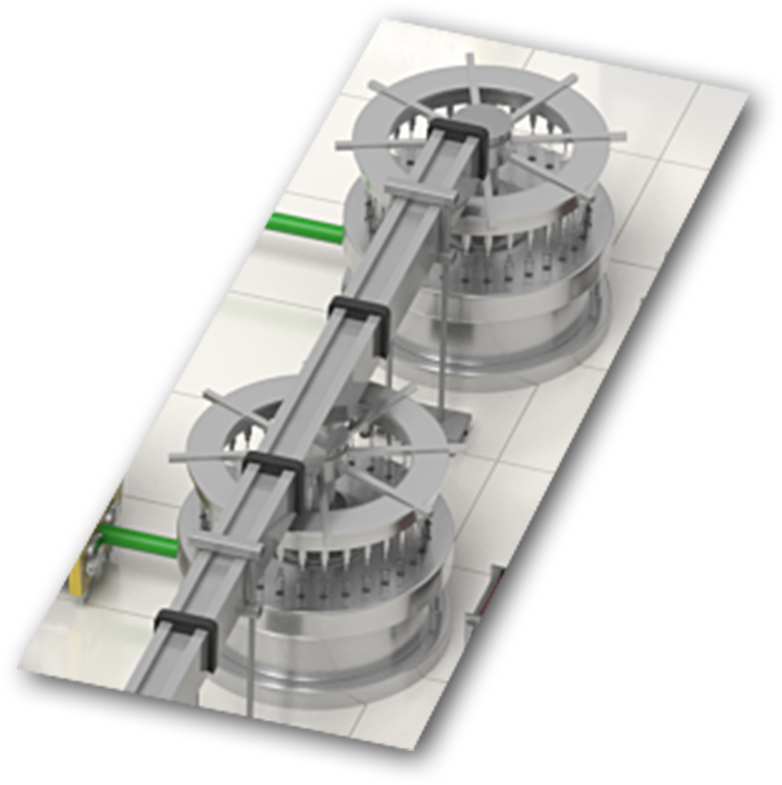

Airveyor

TrackCARETM Airveyor Cleaner is designed to clean and lubricate PET airveyor tracks, using a minimal amount of time and labor.

Benefits for our Beverage Customers include:

- Product Quality – by maintaining clean airveyor surfaces

- Ability to clean during production, reducing scheduled downtime

- Productivity – resulting from reduced bottle jams

- Safety – no need to manually clean difficult-to-reach areas

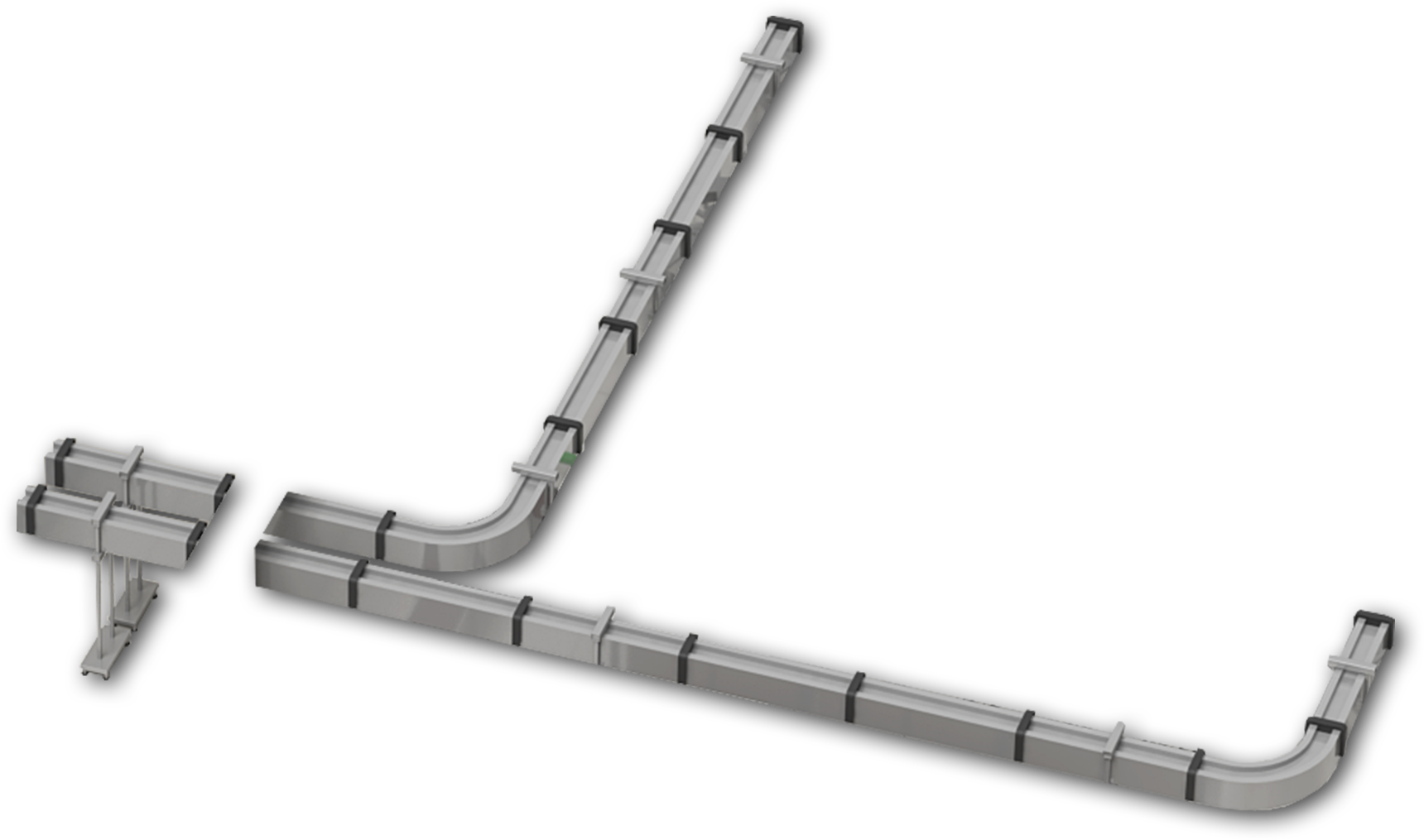

Conveyors

The DryExxTM family of conveyor lubricants enhances the mobility of PET, aluminum, and glass packages on plastic and stainless steel conveyors. Our DryExx dry lubrication systems are silicone-based and can reduce lube system water use by up to 97%.

Additional benefits include:

- Utility savings

- Reduced COD/BOD

- Safe worker environments – no foam

- Cleaner nozzles and conveyors

- Peroxide spend reduction

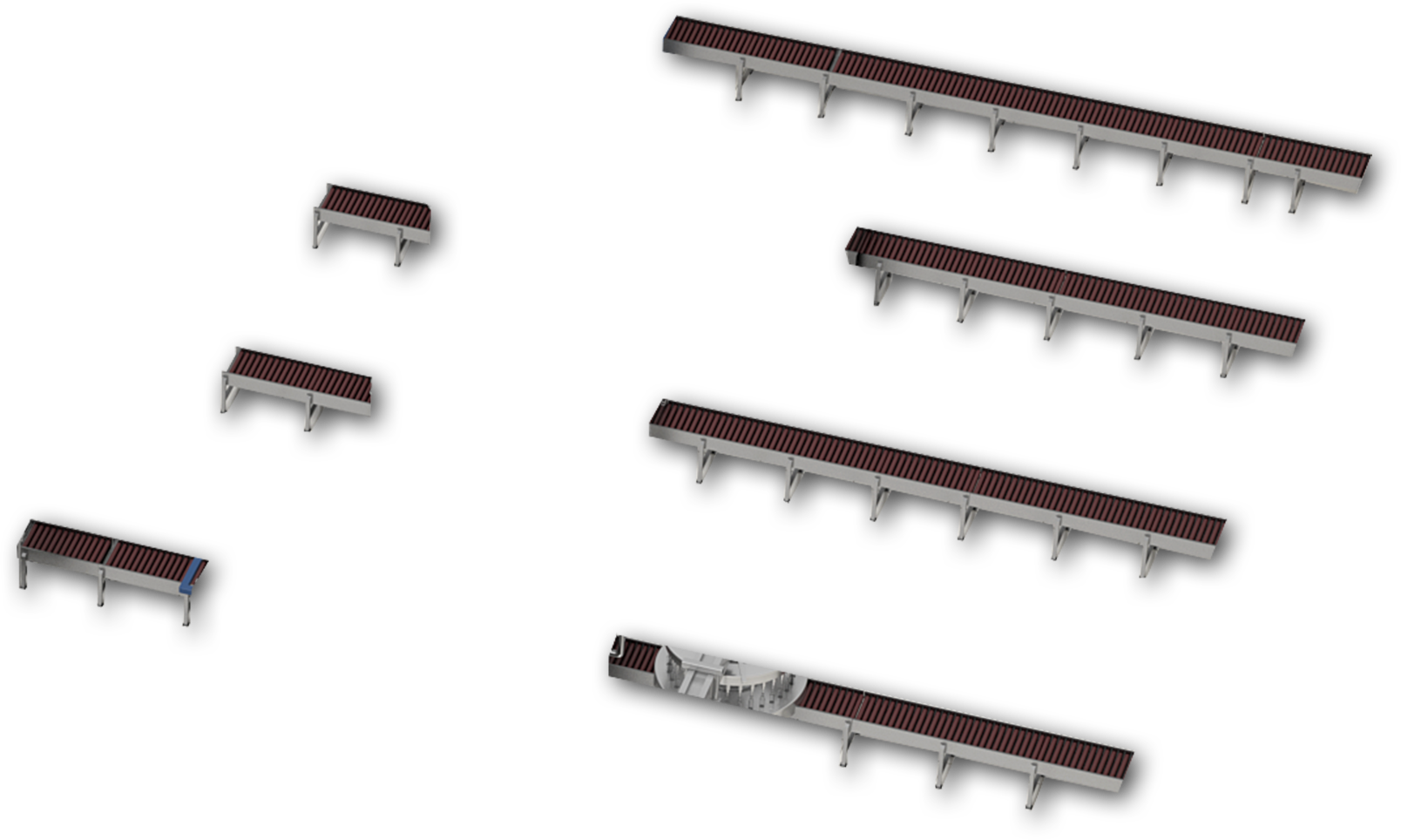

Cooling Tunnel

As Beverage Plants have reduced water usage, water loss in Cooling Tunnels and Warmers has decreased, organic loading has increased and the need for bacteria control has become even more critical.

3D TRASAR Technology for Canning & Bottling ensures Free Chlorine residuals throughout the cooling tunnel and warmer. By combining the Nalco Oxidant Analyzer with our patented 3D TRASAR the result is a low maintenance, comprehensive process water monitoring and control system.

Additional benefits include:

- Delivers robust, consistent and accurate measurement

- Controls bacteria by reducing tunnel contamination

- Prevents product holds, thereby reducing total cost of operation

- Optimizes water usage

- Access to real-time system data via performance dashboards

- Confidence that system experts are watching your system 24/7

Warmer

As Beverage Plants have reduced water usage, water loss in Cooling Tunnels and Warmers has decreased, organic loading has increased and the need for bacteria control has become even more critical.

3D TRASAR Technology for Canning & Bottling ensures Free Chlorine residuals throughout the cooling tunnel and warmer. By combining the Nalco Oxidant Analyzer with our patented 3D TRASAR the result is a low maintenance, comprehensive process water monitoring and control system.

Additional benefits include:

- Delivers robust, consistent and accurate measurement

- Controls bacteria by reducing tunnel contamination

- Prevents product holds, thereby reducing total cost of operation

- Optimizes water usage

- Access to real-time system data via performance dashboards

- Confidence that system experts are watching your system 24/7

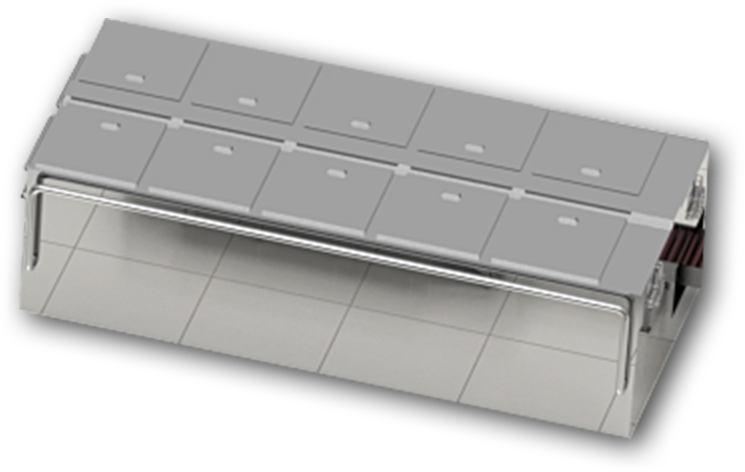

Bottle Washer

Outside of North America, the Bottle Washer is the main driver of water and energy consumption in the packaging area. Ecolab offers a modular and controlled approach that unlocks the optimization potential in the bottle washer to deliver significant reductions in energy, water and glass breakage. Our cleaning & sanitizing additives tackle all the key needs of beverage manufacturers, such as removing labels & glues, molds & rust rings, and insect larvae.